- HOME

- UNTIL THE FILE IS MADE

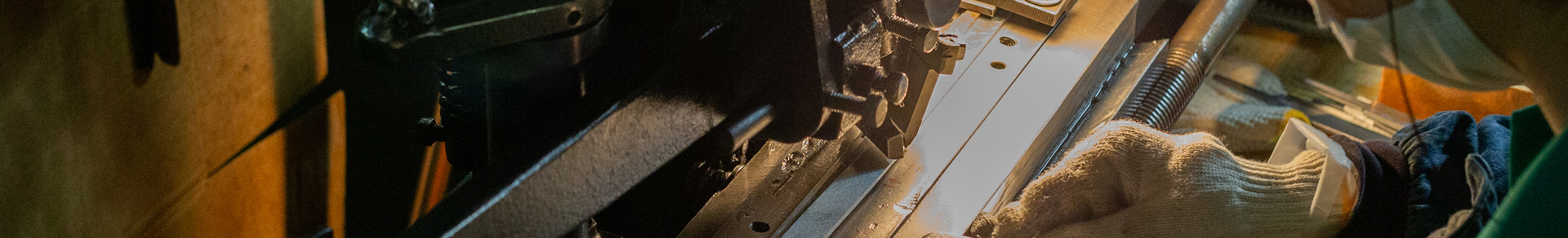

Supporting and changing the manufacturing site, Tsubosanyasuri.

Tsubosan produces millions of files annually in Nigata, Kure City, a major production area for files that boasts a 90% share of the Japanese market.

We have developed and manufactured more than 2,000 types of files that are easier to work with and that can be used with a wider range of workpieces, based on the idea of "providing what customers really need."

Even though we produce a huge amount of products, we are committed to always providing quality-guaranteed files.

It can be scraped as desired and does not clog. Easy to grip and less fatigue. Once you use it, you won’t be able to part with it because of its ease of use and high performance. The secret lies in the careful and sincere handwork of our craftsmen, as well as their refined technical skills and discerning skills.

You can’t make a good file without human "hands" and "eyes". Therefore, at Tsubosan, we continue to pass on the techniques and know-how that we have cultivated since our founding from veteran craftsmen to younger generations of craftsmen.

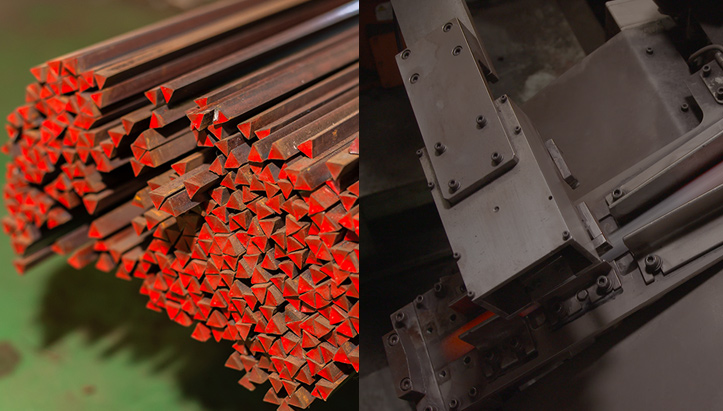

Forging molding

After cutting a long piece of steel and processing it to form the handle, it is forged.

Annealing

The rolled material is annealed to soften it so that it can be sharpened.

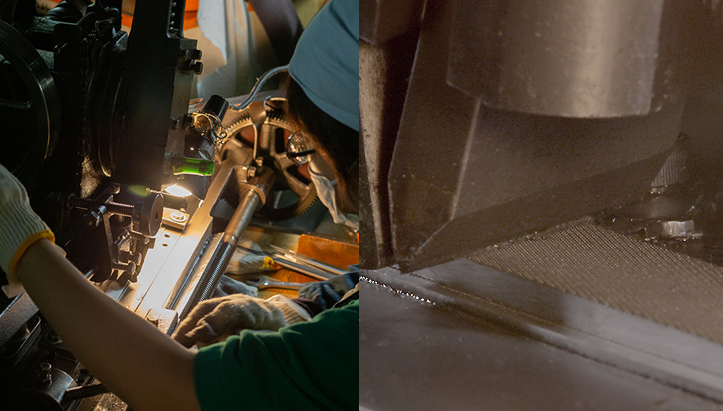

Polishing

Grind the sides and flats separately. If the surface is not polished evenly here, it will affect the most important process of "sharpening" with a file, so high precision is required.

Cutting

Cutting is the most important process, which can be said to be the life of a file. A craftsman skillfully operates a machine with a steel blade called a "tagane" to carve out the "grains" of the file at high speed.

The chisel that affects the sharpness of the file is a special specification unique to Tsubosan. Utilizing the know-how we have accumulated so far, we use different chisels with different angles, heights and thicknesses according to the product to be made.

There are fully automatic machines, but at Tsubosan, craftsmen basically use machines that are operated by their hands and feet.

The reason for this is that even if there is a difference in the thickness of the material, it is possible to flexibly adjust the driving condition of the chisel, and it is easy to respond to special orders with a small production volume.

The work of adjusting the setting position of the chisel according to the product and the work of driving the chisel into the file. In order to carve the eyes evenly, a skilled technique is required.

In addition to checking visually, you can feel the vibrations in your hand and the crisp sound of stamping with your five senses, and you can sharpen sharpness by engraving accurately and powerfully.

Hardening

After sharpening, it is coated with miso and quenched. "Miso" is indispensable for making traditional Japanese files, including Nigata. By applying it before quenching, the salt contained in miso cools the file evenly and supports complete quenching, as well as keeping the "carbon" that is essential for increasing surface hardness from escaping from the blade. It works.

The formula of miso differs from manufacturer to manufacturer and is considered a trade secret. Of course, Tsubosan also uses a secret miso that has been passed down for many years. Depending on the coarseness of the mesh, the thickness of the miso to be applied is also changed.

Inspection

Tsubosan conducts 100% inspection. All manufactured files are checked by human eyes one by one.

While using special JIS standard equipment, we visually check to see if it is over-baked, if it is not quenched too lightly, if it is bent, and so on.

Inspection specialists do not miss even the slightest imperfections that are invisible to the naked eye. Only products that have passed strict inspections are packed and shipped in-house and delivered to you.