About Our File Products

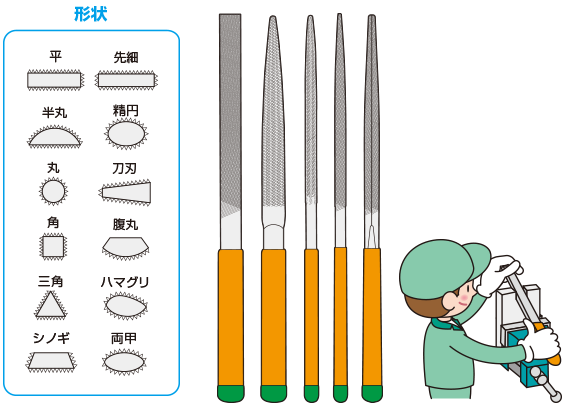

ENGINEER’S FILES(Large size)

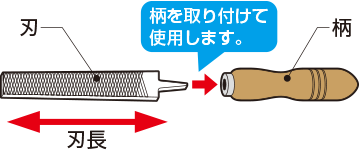

● Used for flattening surfaces and chamfering edges.

● Ideal for hand finishing after machine processing.

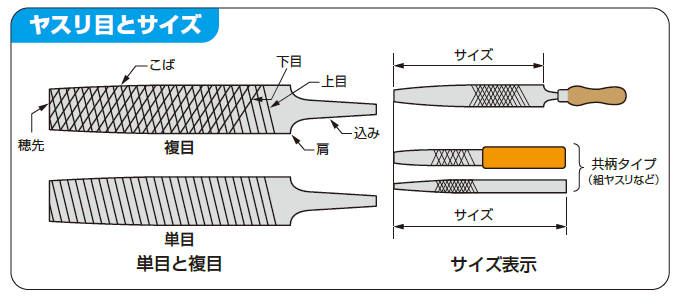

● File size is based on Knife length, not total length.

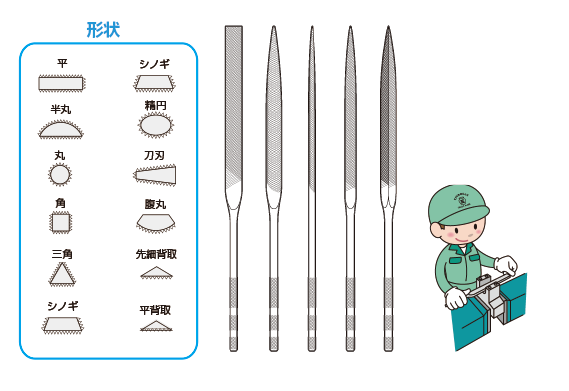

DIE SINKER’S-ASSORTED FILES(Medium size)

● Used for detailed hand finishing.

● Available in 12 cross-sectional shapes.

● Set sizes: 5, 8, 10, 12 pieces.

● 5-piece = 215mm, 8-piece = 200mm, 10-piece = 185mm, 12-piece = 170mm

Precision Files (Small Size)

● Extra-fine teeth for precise finishing.

● Ideal for metal or jewelry work.

● 5-piece = 200mm, 8-piece = 180mm, 10-piece = 160mm, 12-piece = 140mm

Supplement (Set Contents)

● 5-piece set: Flat, Half-round, Round, Square, Triangle 1 each

● 8-piece set: Flat, Half-round, Round, Square, Triangle, Trape Zoid, Flat, Oval 1 each

● 10-piece set: Flat, Half-round, Round, Square, Triangle, Trape Zoid, Flat, Oval, Knife, Balance Edge 1 each

● 12-piece set: Flat, Half-round, Round, Square, Triangle, Trape Zoid, Flat, Oval, Knife, Balance Edge, Clam, Auri-Form 1 each

● 5-piece set: Flat, Half-round, Round, Square, Triangle 1 each

● 8-piece set: Flat, Half-round, Round, Square, Triangle, Trape Zoid, Flat, Oval 1 each

● 10-piece set: Flat, Half-round, Round, Square, Triangle, Trape Zoid, Flat, Oval, Knife, Balance Edge 1 each

● 12-piece set: Flat, Half-round, Round, Square, Triangle, Trape Zoid, Flat, Oval, Knife, Balance Edge, Flat Leaf, Hand Leaf 1 each

Standard files cut only on the push stroke. Avoid applying force on the return stroke to extend the tool’s lifespan.

Skills Competition File

This file is used in skills competitions where top-level technicians compete in precision machining at micron-level accuracy. It features an industry-first Flat design on both ends of the file surface to help ensure balance on the workpiece. A clear coating is applied instead of high-viscosity rust-preventive oil to enhance chip removal and reduce clogging.

Deburring File

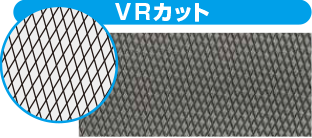

This uniquely designed file is specialized for deburring. By redesigning the angle of the teeth, it adopts a “VR Cut” with a blunter angle than standard files, offering an unprecedented deburring experience. The straight cross-section, rather than a Flat one, improves stability during edge trimming work.

Diamond File

Designed for processing high-hardness materials such as hardened steel, ceramics, and carbide. The diamond particles on the file surface are of high grade and uniform shape, ensuring sharp cutting performance, high removal efficiency, resistance to clogging, and durability. The bent grip design enhances handling and transfers force efficiently.

Files for Power & Air Tools

These files are compatible with electric and pneumatic tools and come in various sizes and tooth patterns using materials such as titanium and CBN (diamond). We offer optimal selections based on application. Air-powered file bodies move the file back and forth automatically upon contact with the workpiece, making them ideal for continuous or long-duration tasks.

Imported Files (Vallorbe)

Vallorbe is a world-class manufacturer of precision and chainsaw files, supporting the Swiss watchmaking and jewelry industries since 1899. All products are made in Switzerland to the highest standards. As Vallorbe’s official importer, Tsubosan offers a wide range of files including sharpening files, rasp files, and saw files, with various shapes, sizes, and tooth patterns available.

Bright 900

Featured in numerous TV and media outlets, “Bright-900” is a popular Tsubosan original product. Using a tough base material and Tsubosan’s original coating technology, it achieves superior surface hardness and revolutionary file performance. From soft to hard materials ? wood, wax, plastic, aluminum, copper, mold steel, stainless, and ceramics ? this file handles it all. It resists clogging, easily removes chips, and maintains sharp cutting. Durability is 3 to 6 times higher than conventional files (varies by material).

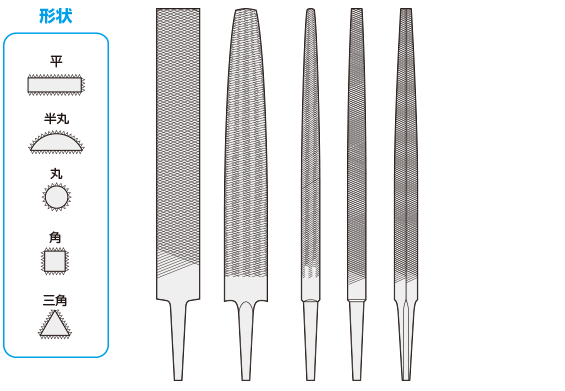

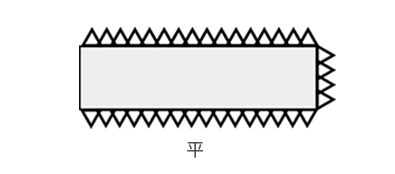

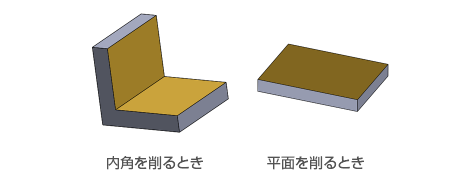

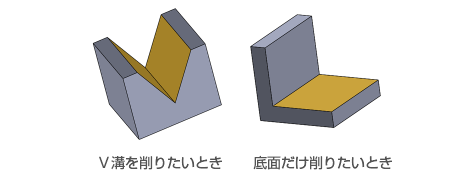

File Shapes

| Formed Shape | File Shape |

|---|---|

|

|

|

|

|

|

|

|

|

|

A basic, flat rectangular cross-section. Mainly used for deburring, grinding, and cutting.

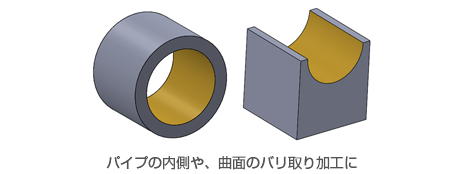

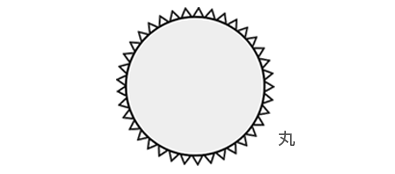

RoundRound cross-section. Its curved surface prevents damage to curved workpieces. Often used to widen holes such as screw threads.

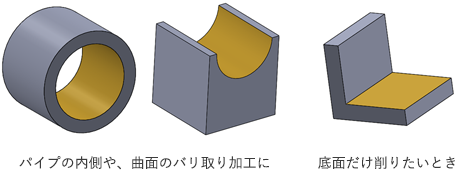

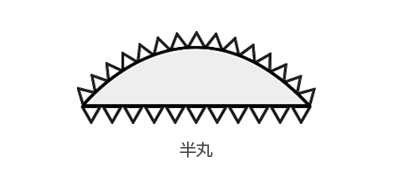

Half-RoundSemi-circular cross-section. Useful for both curved and angled edges. Suitable for pottery, glasswork, and fine finishing.

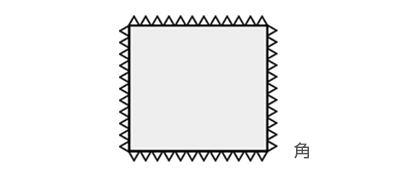

SquareSquare cross-section. Suitable for making or enlarging square holes and 90° angle deburring. Also good for tight spaces due to its slim profile.

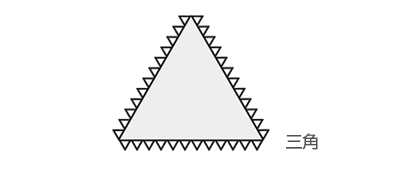

TriangleTriangular cross-section. Ideal for sharpening sharp corners. Also used for saw tooth sharpening (“metate”).

Types of File Teeth

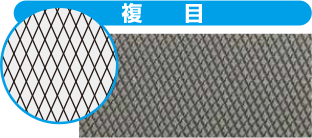

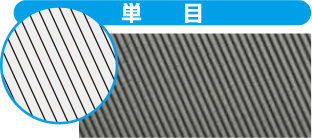

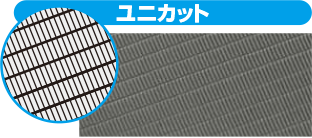

There are several types of file teeth, including double-cut, single-cut, rasp, shari, wavy, and VR cut.

A double-cut file has two sets of crossing diagonal grooves, and is the most common type (also known as crosscut or mesh).

A single-cut file has only one set of parallel grooves spaced evenly.

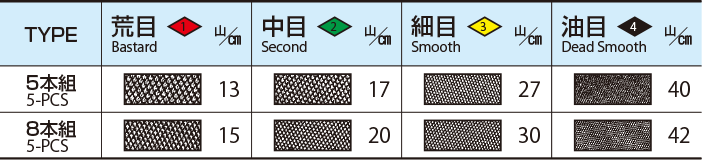

File Tooth Coarseness

In addition to tooth types, files vary in coarseness.

The wider the spacing between grooves, the deeper the cut ? enabling faster removal but leaving a rougher finish.

Coarseness is categorized as: Coarse, Medium, Fine, and Smooth (Oil Cut), from rough to fine.

Even within the same grade, coarseness varies depending on the size of the file.

The number below indicates the number of teeth per centimeter ? fewer teeth means a coarser file.

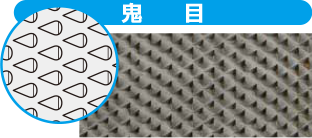

Tooth Shapes and Features

-

The file surface Knifes intersect. This is the most common type, widely used traditionally. Suitable for cutting iron and metalwork. Removes more material than S-cut.

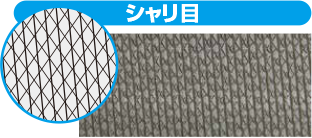

- Interference

The file surface Knifes are arranged in parallel. Used for finishing metal surfaces. Produces a smoother finish than W-cut and is ideal for materials prone to clogging.

-

The file surface has multiple protrusions instead of grooves. Used for woodworking or lead filing. Ideal for processing soft materials like wood, lead, PVC, and plaster. Wood files have coarse teeth on the front and fine teeth on the back. Lead files have coarse teeth on both sides.

-

Features triple-cut teeth for removing more material when working with soft materials.

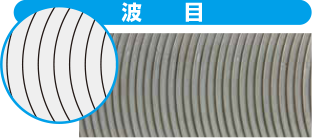

-

The file surface Knifes are curved like a washboard. Ideal for materials like copper and aluminum that are prone to clogging.

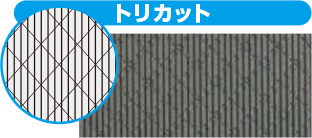

-

Also a triple-cut like the previous one, but each tooth is angled uniquely. The oblique Knifes cut into hard-to-machine materials, while the parallel Knifes provide a smooth finish.

-

Also known as a multi-purpose cut. The chip-breaker grooves function effectively, combining the smooth finish of an S-cut with the cutting feel of a W-cut.

-

Compared to a typical W-cut, the Knife angle is set more obtuse, making it ideal for deburring tasks.

How to Use a File / Filing Techniques

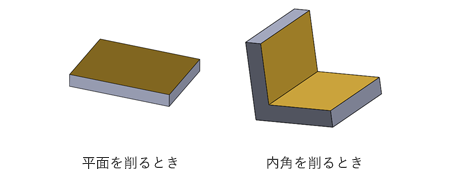

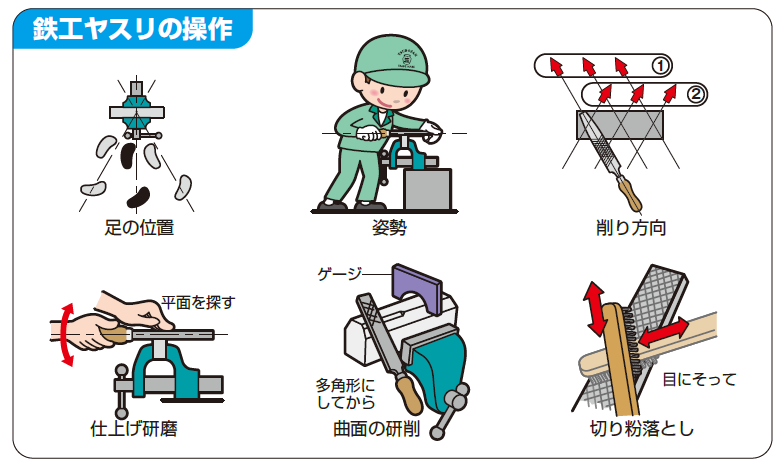

The basic technique of file operation lies in metalworking files. Let’s look at the cutting process to produce a flat surface.

First, secure the material in a vise and position your body properly. Foot placement depends on the direction in which you push the file, as shown in the diagram.

Next, hold both ends of the file horizontally and place it on the material.

Then lower your hips until the elbow of the hand holding the handle is level. With this posture, your hand movement can follow a straight stroke.

Move the file in the axial direction and diagonally across the material.

One reason for the diagonal motion is to prevent material resonance and improve cutting grip.

File from one edge to the opposite edge, then switch directions and file crosswise. The filing marks will also intersect.

This cancels out linear scratches and makes any remaining unevenness more visible.

That’s the second reason. Push the file against the material to cut while moving forward, and reduce pressure when pulling back.

Clogged chips mostly fall off during the pulling motion.

To create an accurate flat surface, align your horizontal strokes precisely with the material surface.

As you approach the finishing stage, press the center of the file with your hand as shown in the diagram to keep full contact and control the filing angle.

Maintain that angle while filing. For the final finish, use a gauge diagonally to check for gaps. If there are none, you’re done.

If chips get clogged midway, remove them with a wire brush. For W-cut files, brush along the direction of both top and bottom teeth.

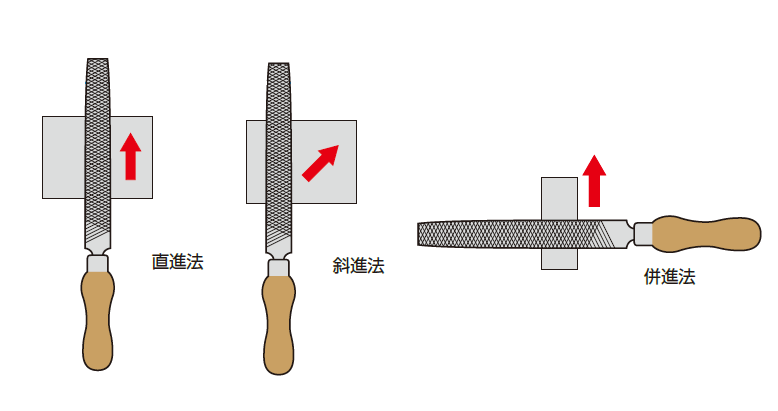

Types of Filing Methods

There are three main filing methods. Choosing the right one according to the situation can make the work more efficient.

Straight Stroke MethodThis is the most common method, where the file is moved straight forward. It is characterized by producing a smooth finished surface.

Diagonal Stroke MethodThe file is moved diagonally forward across the workpiece. This method removes more material and is suitable for rough cutting.

Lateral Stroke MethodThe file is turned sideways and moved forward. It is used for finishing narrow, long pieces or for chamfering to align the file marks.